Precision Machining Division of medium to large dimensions.

Via del Progresso, 40/42 – 36100 Vicenza

Tel: +39 039 2848636 Mail: info@gslexport.it

Zanetti has been working in the processing sector since 1967. They design and build assembled units, automations and individual components for the iron and steel, naval, hydroelectric and oil industries and the main structural works.

“Quality applies to every stage of our production process”.

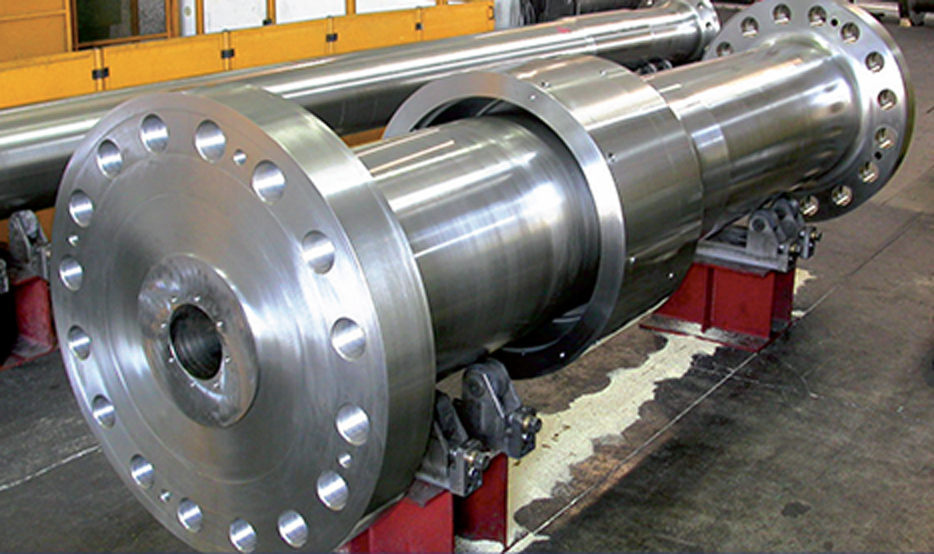

Over the years, the milling, turning and assembly departments have been equipped with the most advanced machinery to satisfy ever more the demands of the market. In the turning workshop a new processing center was introduced, Pietro Carnaghi. It has a turning capacity of up to 6.7 m in diameter, 5 m in height and 200 tonnes. A second addition is the Tacchi HD / 3 105 H lathe, with a capacity of up to 16 m in length and 1600 m in diameter. These additions demonstrate the company’s vision for technological development and production improvement. In the drilling and milling sector, OMZ is able to process workpieces up to 12 m in length, 4 m in height and 50 tonnes, steering shafts from 3 to 20 m up to a maximum weight of 55 tonnes and a maximum diameter of 1800 mm. The high production efficiency and processing of complex geometries are possible thanks to the use of computerized programming, through the CAM Top Solid software.

In addition, measurement technologies have been improved through the introduction of a Faro Laser Vantage Tracker to measure parts over 20 meters with an MPE of 0.0016 mm. OMZ is equipped with a metrological room with 3 sample meters (1, 1.5 and 5 m) to guarantee maximum repeatability and accuracy of measurements.

OMZ strives to improve. Collaborate with Universities, such as the University of Padua and NTNU in Trondheim (Norway), to develop its products in the best possible way (eg aluminum rolls), choose materials (hot and cold mechanical tests, from 20 to 800 ° C), and simulate conditions.